Precision CNC Turning: How to Ensure Quality?

In the realm of precision manufacturing, Precision CNC Turning plays a pivotal role in creating cylindrical components with unparalleled accuracy. To ensure the highest quality in CNC turning operations, attention to detail and adherence to best practices are paramount. Let's delve into the key aspects of ensuring quality in precision CNC turning.

Understanding Precision CNC Turning

What is Precision CNC Turning?

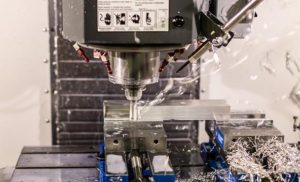

Precision CNC Turning involves the process of rotating a workpiece on a lathe while a cutting tool removes material to achieve the desired shape and dimensions. CNC turning machines utilize computer numerical control (CNC) technology to automate and control the turning process with exceptional precision and repeatability.

Precision Levels Achieved

Precision CNC turning machines are capable of achieving remarkable accuracy levels, with tolerances reaching as low as ±0.005 mm (±0.0002 inches) or finer. This level of precision enables the production of cylindrical components with tight dimensional tolerances and smooth surface finishes, meeting the exacting requirements of various industries.

Ensuring Quality in Precision CNC Turning

Machine Calibration and Maintenance

Regular calibration and maintenance of CNC turning machines are essential for ensuring quality and accuracy. Proper alignment of machine components, including the spindle, tool turret, and tailstock, minimizes geometric errors and ensures consistent machining performance. Additionally, routine maintenance tasks such as lubrication, cleaning, and inspection of critical components prevent premature wear and prolong machine service life.

Tool Selection and Optimization

Selecting the right cutting tools and optimizing cutting parameters are critical for achieving quality results in CNC turning. Utilize high-quality carbide inserts with appropriate geometries and coatings to enhance tool life and cutting performance. Optimize parameters such as cutting speed, feed rate, and depth of cut to maximize material removal rates while maintaining dimensional accuracy and surface finish.

Material Considerations

The choice of materials significantly impacts the quality and machinability of CNC turned components. Select materials suitable for CNC turning operations, such as free-cutting steel alloys, aluminum, brass, and engineering plastics. Consider factors such as material hardness, thermal conductivity, and chip formation characteristics to ensure optimal machining conditions and minimize tool wear.

Rigorous Inspection and Quality Control

Implement rigorous inspection and quality control measures throughout the CNC turning process to verify dimensional accuracy and surface finish. Utilize precision measurement tools such as micrometers, calipers, and surface roughness testers to verify part dimensions and surface integrity. Perform in-process inspections and final inspections to detect any deviations from specifications and ensure compliance with quality standards.

Continuous Process Improvement

Embrace a culture of continuous process improvement to drive quality enhancements in CNC turning operations. Analyze machining data, identify areas for optimization, and implement corrective actions to address root causes of quality issues. Encourage feedback from machinists, engineers, and quality assurance personnel to identify opportunities for efficiency gains and quality improvements.

Advantages of Precision CNC Turning

High Productivity and Efficiency

Precision CNC turning offers high productivity and efficiency, with the ability to produce cylindrical components rapidly and accurately. The automated nature of CNC turning reduces setup times, minimizes idle time between machining operations, and optimizes material utilization, resulting in faster cycle times and lower production costs.

Versatility and Flexibility

CNC turning machines provide versatility and flexibility to accommodate a wide range of part geometries and materials. With multi-axis machining capabilities and programmable tooling, CNC turning can produce complex components with intricate features and contours, eliminating the need for secondary machining operations and reducing overall lead times.

Superior Surface Finish and Dimensional Accuracy

Precision CNC turning delivers superior surface finish and dimensional accuracy, meeting the most stringent quality requirements of various industries. The ability to achieve tight tolerances and smooth surface finishes ensures the production of high-quality components that fit seamlessly and perform optimally in their intended applications.

Conclusion

Ensuring quality in precision CNC turning requires meticulous attention to detail, proper equipment maintenance, optimized machining parameters, and stringent quality control measures. By adhering to best practices and embracing continuous improvement initiatives, manufacturers can consistently deliver precision-turned components of the highest quality. For top-notch precision CNC turning services, visit Precision CNC Turning today.